Affordable and High Quality Media Blasters

January Specials and Featured Sandblasting Cabinets

Assembly NOT Required

Affordable and Budget Friendly

Cyclone sandblast cabinets are high quality and made in the USA, and we make them affordable. But what exactly is high quality? We like to think that high quality means not only the components in a product, but also the work that goes into the product. For Cyclone, that includes the all laser cut welded steel and construction that goes into our cabinets.

No Leaks!

They don’t leak! As a result, no abrasive on your floor or across your work environment. High quality construction also includes the hoses, barbs, grates and nozzles in our equipment. These components have to handle the brutal forces of abrasive sandblasting time and time again. Therefore, we make sure we put the right pieces together to keep you blasting longer. Finally, being budget friendly does not mean that you are getting “cheap” or inferior products. We don’t cut corners and we don’t take shortcuts. We simply make the effort to build strong, powerful, abrasive blasting cabinets that won’t break your bank to earn your business time and time again.

The Lineup – DWS-6035 and FT-6035

The large FT-6035 and DWS-6035 reside on the same basic cabinet chassis. In fact, they both have full top opening lids and side doors to permit large parts and easy access. The only difference in the 6035 options is that the “DWS” is a dual workstation cabinet. This flexibility allows two people to blast at the same time or even one person easily moving between stations. There are two guns and foot pedals and of course two access ports. This combination can make the work must more efficient.

The Best Sandblasting Cabinet

When it comes to the FT-6035, make no mistake, this is one of the best and most popular sandblast cabinets on the market. It’s an ideal combination of height and width. As mentioned, the full top and side door gives flexible access to the interior of the cabinet. The height of the blasting platform inside is just right to make lifting parts into the cabinet easy. The 14 CFM sandblast gun is controlled by a foot pedal. A foot pedal operated system can be less tiring compared to a trigger system if you are blasting for greater lengths of time.

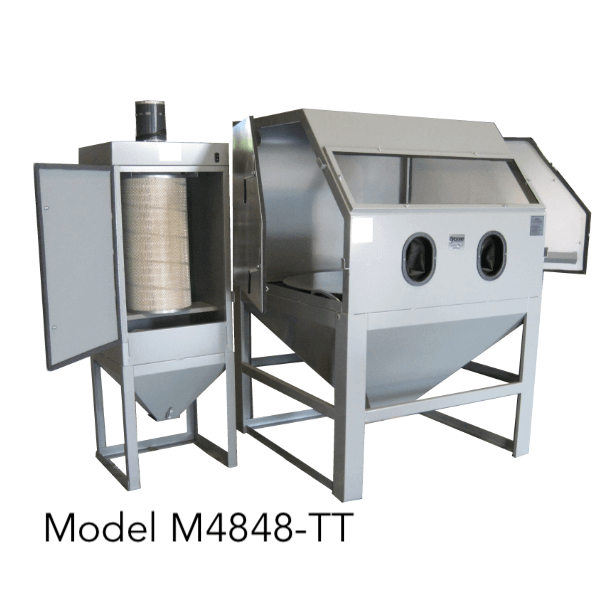

Shown here, the M4848-TT and the DC-4000 connected.

Large Sandblasting Cabinet Capacity

Meet the M4848-TT

M-4848-TT Large Sandblasting Cabinet

If you need a large sandblasting cabinet, this is it. With a massive interior and a large turntable capable of holding over 700 pounds, the M4848-TT is waiting for you. A tremendously powerful sandblast gun with 35 CFM and a tungsten carbide nozzle make efficient work on any surface you need blasted. This large cabinet has two very large side doors. They easily allow large parts in and out of the unit. The worktable height inside the cabinet makes getting heavy parts into and out of the cabinet. A very large view window and excellent lighting inside gives you great visibility while working. And when it comes to visibility, don’t forget a dust collector!

The DC-4000 Dust Collector

When you are blasting inside a cabinet, the powerful airflow and abrasive media creates a dusty environment. This can create many problems for users, the most important being loss of visibility. To combat that we include a DC-4000 dust collector with our M4848-TT. The DC-4000 boasts an impressive 400 CFM of airflow. the DC-4000 turns the air over (cycle time) in the cabinet over 10 times per minute. The bottom line is that the blasting cabinet interior remains visible while you work.

We would love to hear from you. Whether we can answer a question or help make a product decision. We do not have a complicated phone system, you call – we answer! The same is true with our email. We personally respond to your inquiries, no automated replies.