Sandblasting Cabinets &

Abrasive Blast Equipment

Need an affordable sandblasting cabinet made in the USA? We provide a full catalog of sandblasting equipment. From large to industrial size blast cabinets and nearly everything between, we have a cabinet for your projects. Most importantly, we make it affordable and we do not sacrifice quality. Along with our blast cabinets, we carry dust collection equipment, sandblaster parts, and abrasive media.

Proudly Made in the USA – Dowagiac, Michigan

Affordable High-Quality Sandblasting Cabinets and Supplies.

Looking for a good sandblasting cabinet that is made in America, is powerful and won’t cost a fortune?

Bargain Equipment – Save Money!

One M4848 + DC4000 with cosmetic issues, still new, just dents/scratches. Your price, $3470 + freight.

Featured Blasting System

PT-100-SK – The Side Kick – $1107 + Freight

The PT-100-SK is a unique system. Two blasters in one. Connect to your existing blast cabinet to get pressure blasting power. Or, use as a stand alone pressure blasting tank. Made in the USA – ASME certified pressure tank. Photos show unit attached to cabinet – CABINET NOT INCLUDED.

Features

- Includes components to connect to blast cabinet.

- 23 CFM pedal operated tungsten carbide blast nozzle.

- Easy to roll wheels

- 10′ sandblast hose

- Easily disconnects and serves as a stand-alone pressure blast tank.

- Does not include blast cabinet.

- Ships by UPS

Featured Blast System

DP-38 Direct Pressure Cabinet: $3700 + Freight

Affordable Direct Pressure Sandblasting Cabinet

Quality built, made in the USA, pressure sandblasting cabinets. Affordable and easy to use.

- Full Top Opening.

- 23 CFM @ 100 PSI

- Foot Pedal Operated

Learn more and watch it in action!

Full Line of Abrasive Blasting Equipment

Our BLOG offers ideas and suggestions and our documentation section has our user manuals and troubleshooting techniques. We build custom sandblast cabinet and dust collector work too. We would love to work with you, if you can’t find something call or email us and we will help.

Why Choose Cyclone?

The Best Sandblasting Cabinet for the Money

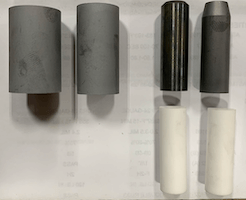

Cheap cabinets are out there but not here. Often, cheap cabinets are imported and require your time for assembly. We manufacture our equipment in Dowagiac, Michigan – USA. And, our cabinets arrive fully assembled. Welded steel construction, solid doors, and a powder coat finish. And don’t forget flexible and powerful sandblasting gun systems. Blast gun configurations vary on use and one size does not always fit. Our pencil/wand and our pistol grip systems are pedal operated. Additionally, we offer trigger operated guns as well. We offer some advice on these options in this article.

High Quality & Affordable Abrasive & Sandblasting Cabinets

The Best Sandblast Cabinets

Cyclone has 40+ years of industry experience and knowledge. Above all, we deliver powerful high-quality abrasive sandblasting cabinets, equipment and supplies. Most importantly, we make it budget friendly. Everything that leaves our facility must pass a tough quality inspection. All this is done by members of our local community. We take great pride in labeling our equipment Made in the USA. As a result you get the best sandblasting cabinets, supplies and equipment Made in the USA at affordable prices.

Sandblasting Cabinets & Service

Searching for a sandblasting cabinet, search no further. Versatile cabinet tops and side doors, comfortable gloves, great lighting, and big view windows are a few more of our great features. Also, our equipment is easy to use and maintain.

Above all else, you get the best sandblasters and supplies at affordable pricing. Finally, we’re here for you. Our team knows our equipment and how it can help achieve your goals. Call our email us with any questions you may have.

Fully Assembled Sandblast Cabinet

Why is this so important? First, if you search for a sandblasting cabinet and read reviews, you will come across entries talking about bolts. Many blast cabinet are inexpensive. Please make sure to read the details. Cheaper cabinets will likely require you to assemble the cabinet.

Bolt on legs and bolt together blast chambers will make a sandblasting cabinet unsteady. Most noteworthy, bolts introduce possible media leaks. To avoid these problems, we weld our cabinets to make them sturdy. And this process ensures that our cabinets won’t leak. Above all else, you get your blast cabinet in one piece. As a result, you connect the air, add media, and get to work right away.

We cover many of our blast cabinets in detail on our YouTube channel. You can also see us unbox them. In fact, we also demonstrate how effective our sandblasting machines are against rusty metal, glass, wood, and much more.

What are Abrasive Sandblasting Cabinets?

Abrasive blasting and sandblasting cabinets refer to the same process. However, a blast cabinet is just a chamber. The chamber contains the powerful stream of abrasive media. The abrasive media determines whether you are “sand” blasting, “bead” blasting, or “shot” blasting. To sum it up further, please read our article. Above all else, never use sand in your sandblaster. Silicosis is a very real danger. Cyclone provides alternative abrasive media to sand.

California Proposition 65

We make our sandblasting cabinets from steel. Proposition 65 concerns the element nickel in steel. Although, almost all steel products contain some nickel. As a result, Nickel is a listed as substance on the California Safe Drinking Water and Toxic Enforcement Act of 1986. Therefore, throughout our site and on our products we include such a warning. Additional information about proposition 65 is found here.

Still Need Help?

Can’t find something? Click here to contact us and we will help you.