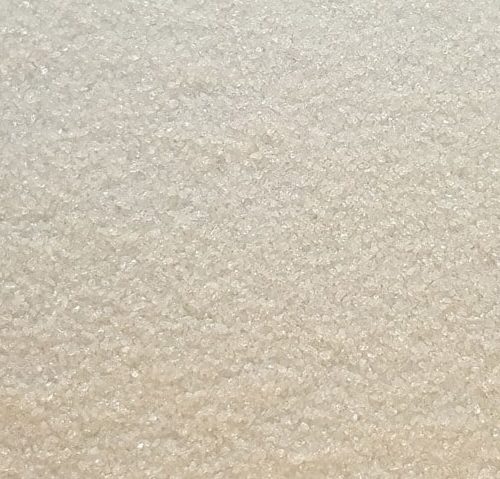

Glass Bead Media

We offer glass beads in 50 pound pails. You can purchase a single pail or multiple pallets. Pricing is given below once you select a grit size. We simply need a location to ship to for a freight quote. Call or email us for volume pricing. Click “Description” below for more information about glass bead media.

Description

Glass bead media is one of the most popular bead blasting abrasives for sale today. This all-purpose abrasive media is ideal for honing and polishing parts. You can also peen, blend, finish, and remove light burrs. Another very popular use is etching or frosting glass. Glass bead blasting is ideal for cleaning for most light foreign matter.

Paint, rust, scale and surface residues are some of the common removal uses. Glass bead blasting generally will not change dimensional tolerances and can detect weld and solder flaws.

Glass bead abrasive is typically consumed at a slow rate in bead blasting equipment. Additionally, the blast beads survive multiple impacts, and thus can be recycled several times. Glass bead blasting media is usually made from recycled glass and is chemically inert. Therefore, they tend to leave no ferrous or other undesirable residue on the surface. When you properly use glass bead media, it leaves a controlled and clean finish on the prepared surface.

If you want to know more about glass bead blasting abrasive, we have this page for you to look over. When you are ready to purchase, you can call or email us and we can assist. If you have any further questions we are ready to help you. We value your business and would be happy to be your glass bead blasting media supplier.

Please select a Glass Bead Media Grit Size from the drop down, then the “Get a Quote Button” and we can prepare a price that includes shipping. Our glass beads come in 50 US Pound (Plastic Pail) increments.