DP 38 Pressure Sandblaster Cabinet

Pressure Sandblaster Cabinet – Model DP-38

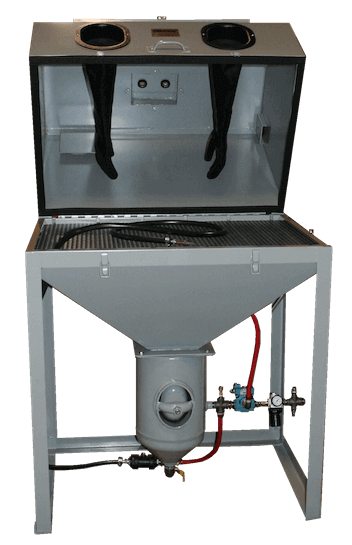

The DP38 is one the best pressure blaster cabinet for sale available today! The large cabinet interior provides ample space for small to large work pieces. Also, the cabinet interior is well lit. A large view window permits the user to comfortably watch as the blasting takes place. Comfortable rubber gloves and an easy to use foot pedal are just a few more features that make this pressure sandblaster an amazing blast cabinet.

Fully Assembled Pressure Blast Cabinet

The unit is fully assembled upon arrival. Because of this you won’t spend time with dozens of bolts to put it together. Also, because of its welded 16 gauge steel and sealant, this unit won’t leak. The welded steel also adds tremendous strength. This means it will support bigger parts and will not wobble during blasting.

Easy to use Sandblaster

We designed this sandblaster to deliver high pressure power at a low price. We also want it to be easy to use. As a result the DP-38 direct pressure sandblaster comes packed with features. First, it is sturdy and has an easy open lid. Because of this it is comfortable for the user to easily get parts in and out of the cabinet. Next, a large view window is installed. The view window is protected on the inside to reduce the damage the abrasive media creates upon impact. Because we include a foot pedal, user fatigue is reduced. We specially designed our sandblast gun so that it easier to use for longer periods.

Other Pressure Sandblaster Cabinet Features

A safety valve comes installed that shuts off air when the lid is open. The DP38 comes complete with a foot pedal operated sandblaster gun and tungsten carbide nozzle. We include many great accessories like: air gauge, regulator to control air flow, and an internal media screen. This way, we protect any harmful debris from reaching your pressure system.

Dust Collector Not Included

The DP38 direct pressure cabinet does not include a dust collector. We recommend our powerful DC-4000 sandblast dust collector. The DC-4000 produces a powerful 400 CFM and works perfectly to keep visibility clear inside the blast cabinet. The cabinet comes with a light receptacle and on/off switch. The switch controls an additional receptacle for the included sandblast dust collector. Therefore, you control the entire cabinet with one easy on/off switch location on the cabinet.

Pressure Sandblaster vs. Gravity Blasters

Pressure blasting is vastly different from a gravity fed abrasive blaster. A pressure blast cabinet is given a supply of air. Then, when you are ready, the user is able to open a blasting valve. After opening the valve, the powerful stream of abrasives hits the target. Once in contact, the abrasives make quick work. Higher pressure means higher velocity and faster cleaning, in most circumstances.

Flexible Abrasive Media Choices

This pressure blast cabinet can handle abrasives like white or brown aluminum oxide, glass beads, silicon carbide, or blasting garnet. We supply a full catalog of abrasive media. We do not recommend steel shot and under no circumstances should you ever use sand in an abrasive cabinet. Read more here to learn about the dangers of using sand in an abrasive blasting cabinet. Sandblasting Safety

See it in Action

WARNING: This cabinet is constructed from steel. In accordance with proposition 65 we are complying by indicating that steel has been known to contain Nickel. Nickel is a chemical known to the State of California to cause cancer. For more information go to http://www.P65Warnings.ca.gov

Description

Pressure Sandblaster Cabinet – Model DP-38

The DP38 is one the best pressure blaster cabinet for sale available today! First the large cabinet interior provides ample space for small to large work pieces. Next, the cabinet interior is well lit. A large view window permits the user to comfortably watch as the blasting takes place. Comfortable rubber gloves and an easy to use foot pedal are just a few more features that make this pressure sandblaster an amazing blast cabinet.

Fully Assembled Pressure Blast Cabinet

The unit is fully assembled upon arrival. Because of this you won’t spend time with dozens of bolts to put it together. Also, because of its welded 16 gauge steel and sealant, this unit won’t leak. The welded steel also adds tremendous strength. This means it will support bigger parts and will not wobble during blasting.

Easy to use Sandblaster

We designed this sandblaster to deliver high pressure power at a low price. We also want it to be easy to use. As a result the DP-38 direct pressure sandblaster comes packed with features. First, it is sturdy and has an easy open lid. Because of this it is comfortable for the user to easily get parts in and out of the cabinet. Next, a large view window is installed. The view window is protected on the inside to reduce the damage the abrasive media creates upon impact. Because we include a foot pedal, user fatigue is reduced. We specially designed our sandblast gun so that it easier to use for longer periods.

Other Pressure Sandblaster Cabinet Features

A safety valve comes installed that shuts off air when the lid is open. The DP38 comes complete with a foot pedal operated sandblaster gun and tungsten carbide nozzle. We include many great accessories like: air gauge, regulator to control air flow, and an internal media screen. This way, we protect any harmful debris from reaching your pressure system.

Dust Collector Not Included

The DP38 direct pressure cabinet does not include a dust collector. We recommend our powerful DC-4000 sandblast dust collector. The DC-4000 produces a powerful 400 CFM and works perfectly to keep visibility clear inside the blast cabinet. The cabinet comes with a light receptacle and on/off switch. The switch controls an additional receptacle for the included sandblast dust collector. Therefore, you control the entire cabinet with one easy on/off switch location on the cabinet.

Pressure Sandblaster vs. Gravity Blasters

Pressure blasting is vastly different from a gravity fed abrasive blaster. A pressure blast cabinet is given a supply of air. Then, when you are ready, the user is able to open a blasting valve. After opening the valve, the powerful stream of abrasives hits the target. Once in contact, the abrasives make quick work. Higher pressure means higher velocity and faster cleaning, in most circumstances.

Flexible Abrasive Media Choices

This pressure blast cabinet can handle abrasives like white or brown aluminum oxide, glass beads, silicon carbide, or blasting garnet. We supply a full catalog of abrasive media. We do not recommend steel shot and under no circumstances should you ever use sand in an abrasive cabinet. Read more here to learn about the dangers of using sand in an abrasive blasting cabinet. Sandblasting Safety

See it in Action

WARNING: This cabinet is constructed from steel. In accordance with proposition 65 we are complying by indicating that steel has been known to contain Nickel. Nickel is a chemical known to the State of California to cause cancer. For more information go to http://www.P65Warnings.ca.gov

Additional information

| Weight | 275 lbs |

|---|---|

| Overall Dimensions | |

| Working Dimensions | |

| Construction | |

| Has Side Door | |

| Electrical Requirements | |

| Cabinet-Lighting | |

| Gloves | |

| Item Weight | |

| Lid Assist | |

| Lid Safety Valve | |

| Lid Style | |

| Nozzle Type | |

| Sandblast Dust Collector | |

| Sandblast System Air Requirements | |

| Sandblast System Quantity | |

| Sandblaster Operation | |

| View Window | |

| View Window Protection | |

| Accessories Included | |

| Nozzle Diameter |